The Art of Design by Harry J. Wirth

Bob Evans was and still is an accomplished scuba diver. He initially became interested in the beauty of sea-life and thus became an underwater photographer. He is quite an accomplished man with the camera as his photographs have been published widely in books and magazines.

Having worked underwater extensively and after logging thousands of dives and expeditions, he became intimately involved with the many difficulties of swimming and maneuvering while attempting to photograph his submariner subjects. Evans literally grew tired of the constant pushing and pulling of water with the conventional fins as he watched the effortless gliding of the fish around him. He had observed and continues to this day his observation of water as a three-dimensional living substance. He realized the fin cannot be designed with the typical two-dimensional mentality.

Another observation was the faster, more efficient fish had a split tail as a main thrusting feature. All of the fins on the market at the time were flat single fins. As Evans puts it, the flat type is very clumsy and inefficient for swimming and diving. The reinforcement ribs restrict water flow around the fin and increase unwanted drag. An astute and observant individual, Evans made intuitive connections between man and nature. He found that the highly evolved fish shapes could be adapted to the human form. Humans are “by nature” one of the most inefficient and awkward objects moving in the water. In essence, he wanted to make the human body more fish like, but in a simple manner with the application of an appropriately designed fin.

The original “Force Fin“, the first model, was physically conceived in 1980, however, the initial concept was realized in the early 1970’s. Evans painfully and diligently evolved the design through many developments of configuration, size and materials. His design methodology was the handling of the design as a dynamic object rather than that of a static one. There was an extensive undertaking of the study of the movements of the foot, ankle, and leg in order to get a good understanding of the dynamic movements of the parts together and separately. An interesting drawing Evans compiled from these leg-movement studies hangs in a prominent place in his studio as a work of art. The innovation was a result of observations of nature in the sea and the application of those observations.

Quickly made of crude materials, many designs were tested, rejected, and refined for quick evaluation. His many configurations were quickly prototyped with chicken-wire and newspaper. His feet would get cuts and bruises as he tirelessly tried concept after concept. Until he arrived at a shape that worked. Evans would make the molds himself in his shop, pull the product and run to the beach to try a new shape. To this day he still follows the same basic “hands-on” method of design development. Many new materials were tried, tested, and evaluated to seek out the best formula suited for his needs with the fin. He needed a stable compound with the necessary snap and flex that would augment and amplify the movements of the leg and foot.

The latest material being applied to the fins is a two-part liquid polyurethane with a good memory of shape. Evans found this material to be quite forgiving in his unique composite molds. Once the fin was formed and pulled from the mold, he discovered the polyurethane had a chain molecular bond arrangement that allowed t to be more durable, yet flexible on the flipper ends or as he calls them the deflecting foils. He found this product while perusing technical journals and saw that it wa good for mallet hammers and heavy duty wheels. It was resilient, yet very durable and flexible.

It is the split ends on the fin that are so special. Observing fish with split fins, Evans saw the tremendous maneuverability of these fish. Trying to do a roll underwater with conventional long stiff fins is quite difficult to accomplish. With the shorter Force Fin, and the flexible tips, which work independently of one-another, maneuverability underwater is smooth and easy. Divers who take their first swim with the Evans’ fins first remark that the fin isn’t working because they feel no resistance. Evans is quick to point out that this is the quality he was striving for, an efficiency that makes underwater kicking effortless.

Another unique feature of the Force Fin is its ability to flex and snap. This action-reaction of the polyurethane structure increases the divers thrust. As Evans states, “when in operation, it has power in one direction and then collapses while throwing water behind in the other direction so that it can get back to where you kick against it without strain.”

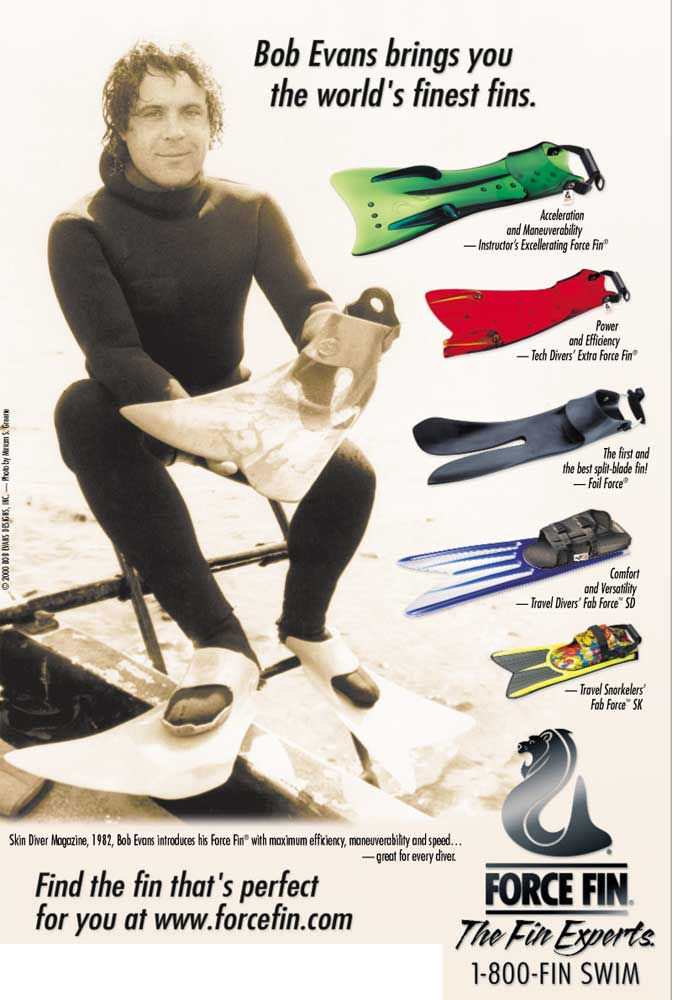

He saw that this action was the same action as what he had seen occur on the fins of a harbor seal on a slow motion video. The Force Fin is an elegant, organic, fluid-formed device that becomes a natural extension of the human leg. Looking rather strange in our dry conditions walking about on the pier, once in the water the beauty of the design is immediately apparent and functionally is better and more efficient than any other fin on the market. Other models followed as the design became more widely accepted. He now has the “Beaver”, the “Rip Force“, the “Tan Delta” and the most advanced the “Extra Force” with adjustable “winglets“.

The “Extra Force Fin” is an adjustable fin to suit the diving and the kicking preferences of the diver. Two, independent, small winglets are attached to either side of the fin. These are mounted with hex-head bolts to allow for adjustment in the field. A diver can increase thrust of the stroke by moving these winglets in or out dependent on the performance desired.

Recently, the US Department of the Navy conducted exhaustive test of many diving fins. Bob Evans’ Force Fins came out on top in the tests. The tests concluded that divers using the Force Fin used less oxygen while active in diving than with any other design. Interestingly enough, the elite Navy Seals teams use the Force Fin as further proof of their superiority as a dive fin. “Eventually”, as Evans states, “all fins will be made this way.”

The Force Fin is continuing to catch on. The sales have increased to such a high level, Evans has to consider now the future of his small company and where he wants to go with it. His desire is to design newer fins and try new technologies, but at present the pressure of meeting the tremendous consumer demand for his superior product is taking most of his time.

— Harry J. Wirth for “The Art of Design: The Innovative Designs of Bob Evans, Erik Buell and Burt Rutan, Design ist okay Innovationstransfer, Herausgegeben von Heiko Bartels, Bauhaus-Universitat Weimarn, Universtatsverlag, 2000

Reprinted with the permission of

Harry J. Wirth © 2000